Product Development

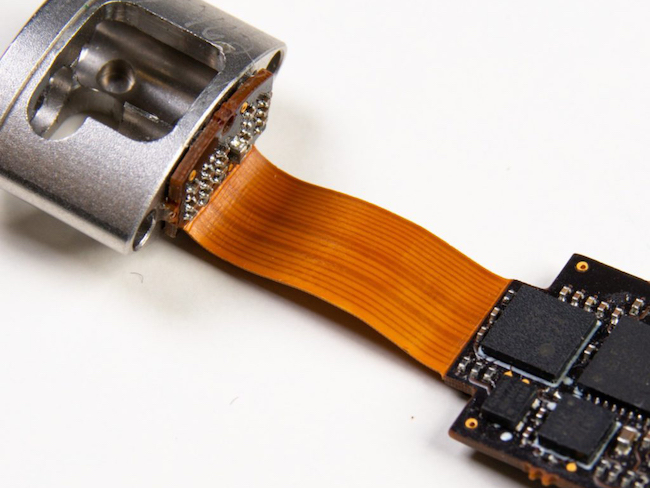

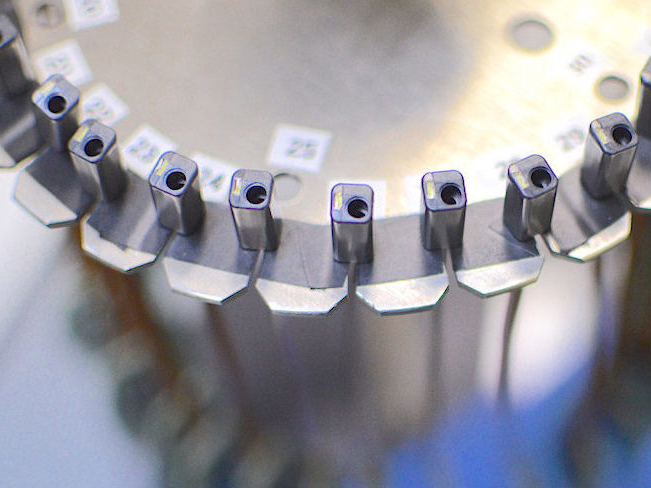

We design optical sub-assemblies, full imaging systems and accessories. We leverage our extensive design experience, optical test expertise, and technology platforms to enable your innovation and accelerate commercialization.

Contract Manufacturing

The Lighthouse development process incorporates design for manufacturability from day one. We understand cost and product performance are both important to our clients. We manufacture optical sub-assemblies, final products, and accessories.

Why Lighthouse?

We take products from concept to commercialization and look to be your manufacturing partner of choice. We typically establish long term partnerships with our clients and understand that your commercial success benefits us as well.

ISO 13485 Certified & Quality Management System

Lighthouse employs a rigorous Quality Management System. We are committed to continually improving the effectiveness of our QMS in accordance with industry best practices. We also encourage client engagement with our QMS.

Our QMS is certified to ISO 13485:2016 and compliant with 21 CFR 820. Our manufacturing facility is FDA registered. We are committed to compliance and achieving customer satisfaction.

Chip on Tip Endoscope White Paper – 5 key questions to ask your team to get started!

Defining optical design specifications for custom chip on tip endoscopes can be a daunting task. In optics, the critical specifications are literally invisible, and it is common that parameters critical to the success of the device are overlooked. Consider:

- Field of View

- Direction of View

- Optical Resolution

- And More!

Resources

The ‘AT THE SPEED OF LIGHTHOUSE‘ resource center is here to help give you insight on Optical Design, Commercialization and Manufacturing.